Introduction: Why OEM Car Radio Development Matters

In today’s automotive industry, the car radio is no longer a standalone entertainment device. It has evolved into a central hub that integrates infotainment, connectivity, vehicle data display, and brand identity. For automotive manufacturers, especially OEM car makers, developing a reliable and competitive car radio system is a strategic project that directly impacts user experience, vehicle value, and long-term brand perception.

OEM car radio development projects are complex, involving cross-functional collaboration between automotive manufacturers, Tier 1 or Tier 2 suppliers, and specialized OEM/ODM manufacturers. From concept definition to mass production, each step requires strict control over quality, stability, compliance, and scalability.

This article outlines the key steps in OEM car radio development projects, based on real-world manufacturing experience, and provides automotive manufacturers with a clear framework to successfully manage and execute such projects.

Step 1: Project Requirement Definition and Feasibility Analysis

Every successful OEM car radio project starts with a clear and detailed requirement definition. At this stage, automotive manufacturers typically provide a Product Requirement Document (PRD) or Technical Specification Sheet that outlines functional, mechanical, and regulatory expectations.

Key Requirement Areas

● Vehicle platform and model lifecycle: vehicle segment, production volume, SOP and EOP timeline

● System platform: Linux or Android car multimedia system

● Display size and resolution: 7”, 9”, 10.25”, 12.3”, or customized digital cluster solutions

● Core functions: radio (AM/FM/DAB), Bluetooth, USB, navigation, camera input, vehicle settings

● Connectivity: wired or wireless Apple CarPlay, Android Auto

● Performance targets: boot time, touch response, system stability

● Environmental requirements: operating temperature, vibration resistance

A professional OEM car radio manufacturer will conduct a feasibility analysis covering hardware capability, software architecture, cost structure, and compliance risks before moving to the next phase.

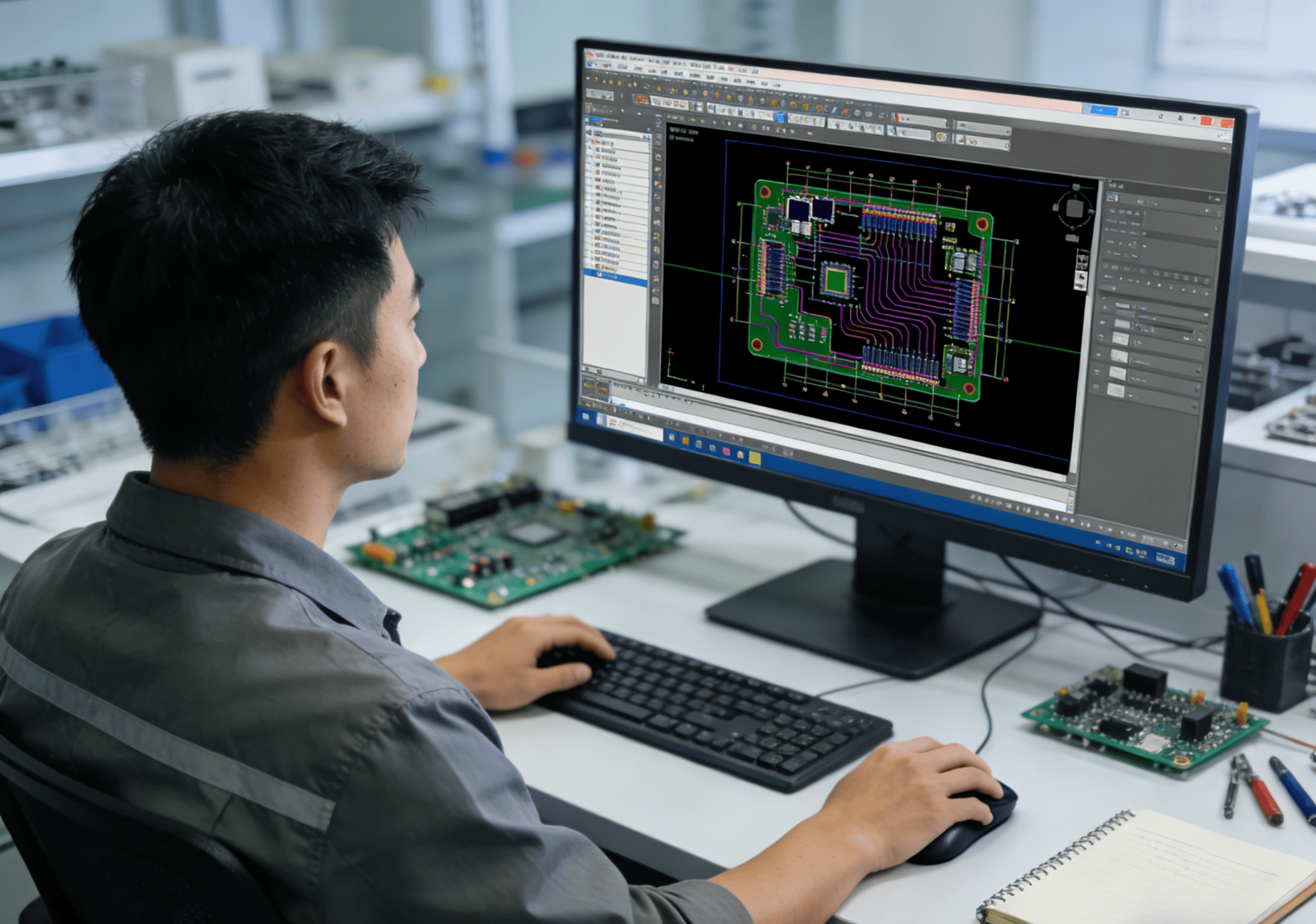

Step 2: Platform Selection and System Architecture Design

Choosing the right platform is a critical technical decision in OEM car radio development.

Android vs Linux Platforms

● Linux car multimedia systems are widely used in cost-sensitive or high-stability vehicle projects. They offer fast boot time, long lifecycle support, and predictable system behavior.

● Android car radio systems provide richer user interfaces, app extensibility, and easier integration of advanced connectivity features. Automotive-grade Android solutions prioritize stability over consumer smartphone features.

Hardware Architecture Design

OEM manufacturers design the core hardware architecture based on:

● Automotive-grade SoC (CPU, GPU, DSP)

● Memory configuration (RAM, eMMC)

● Power management and wide-voltage input design

● RF design for radio, Bluetooth, Wi-Fi, and GPS

● Interface support (CAN, LIN, USB, LVDS, MIPI)

At this stage, Design for Manufacturability (DFM) and Design for Testability (DFT) principles are introduced to ensure scalability for mass production.

Step 3: Industrial Design and Mechanical Integration

For automotive OEM projects, industrial design is not only about appearance but also about precise mechanical integration with the vehicle dashboard.

Key Considerations

● Front panel design aligned with vehicle interior language

● Button and knob layout optimized for driving safety

● Thermal design to ensure stable operation under high temperature

● EMI shielding and grounding structure

● Tolerance control to match vehicle dashboard assembly

Close collaboration between the car manufacturer, ID designers, and OEM car radio factory is essential to avoid costly tooling revisions at later stages.

Step 4: Software Customization and UI Branding

Software is where automotive brands differentiate themselves.

Software Development Scope

● Operating system customization (Android or Linux)

● Boot animation and brand logo integration

● UI/UX design aligned with brand identity

● Multi-language support

● Vehicle setting integration via CAN or LIN

Wireless CarPlay and Android Auto Integration

For modern vehicles, especially premium and luxury models, wireless CarPlay modules have become a standard expectation. OEM development must ensure:

● Stable wireless connection

● Fast pairing and reconnection

● Low latency audio and touch response

● Compatibility with Apple and Google certification requirements

In high-end projects, such as luxury vehicle or sports car applications, software stability and seamless user experience are more critical than feature quantity.

Step 5: Prototype Development and Engineering Validation

After design finalization, OEM car radio manufacturers move into prototype development.

Prototype Stages

● EVT (Engineering Validation Test): functional verification and early risk detection

● DVT (Design Validation Test): design robustness, reliability, and compliance

● PVT (Production Validation Test): mass production readiness

Key Validation Tests

● Functional and stress testing

● Temperature cycling and thermal shock

● Vibration and mechanical shock

● Power fluctuation and load dump testing

● Software stability and long-term aging tests

These steps significantly reduce the risk of failures after SOP.

Step 6: Automotive Compliance and Certification

Compliance is a non-negotiable requirement in OEM car radio development projects.

Common Compliance Standards

● EMI / EMC standards (CE, FCC, E-Mark)

● Automotive-specific standards (ISO, AIS, OEM internal standards)

● Environmental regulations (RoHS, REACH)

OEM manufacturers with in-house testing capabilities and strong experience in automotive compliance can shorten certification cycles and reduce project risk.

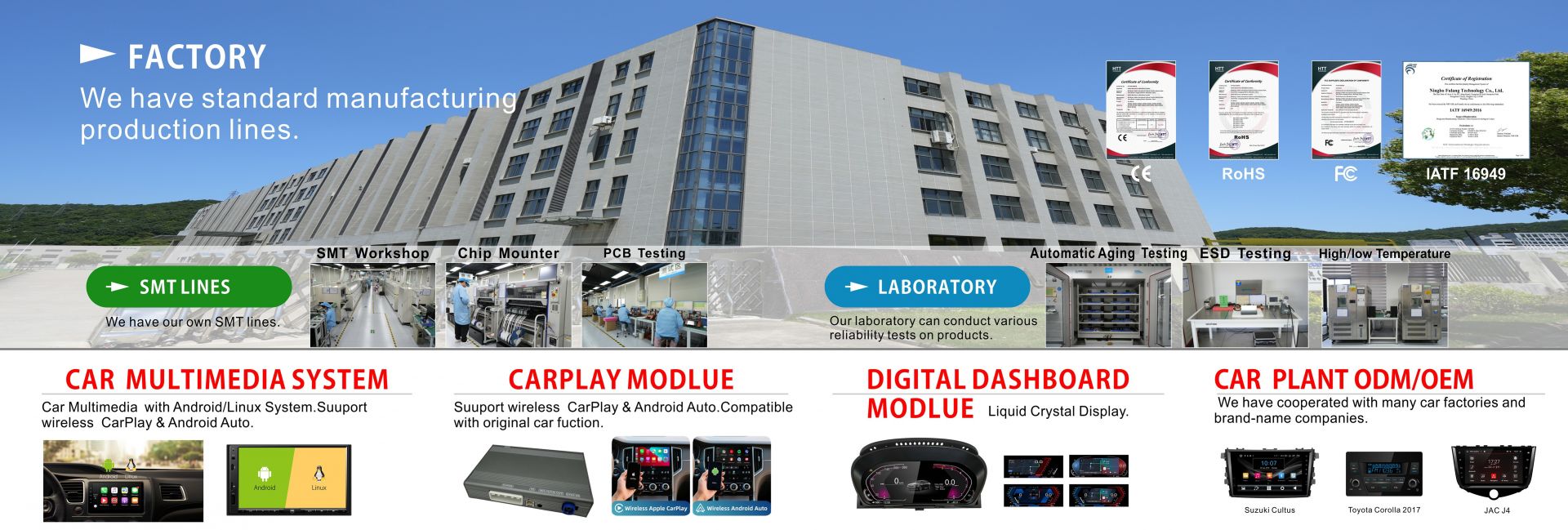

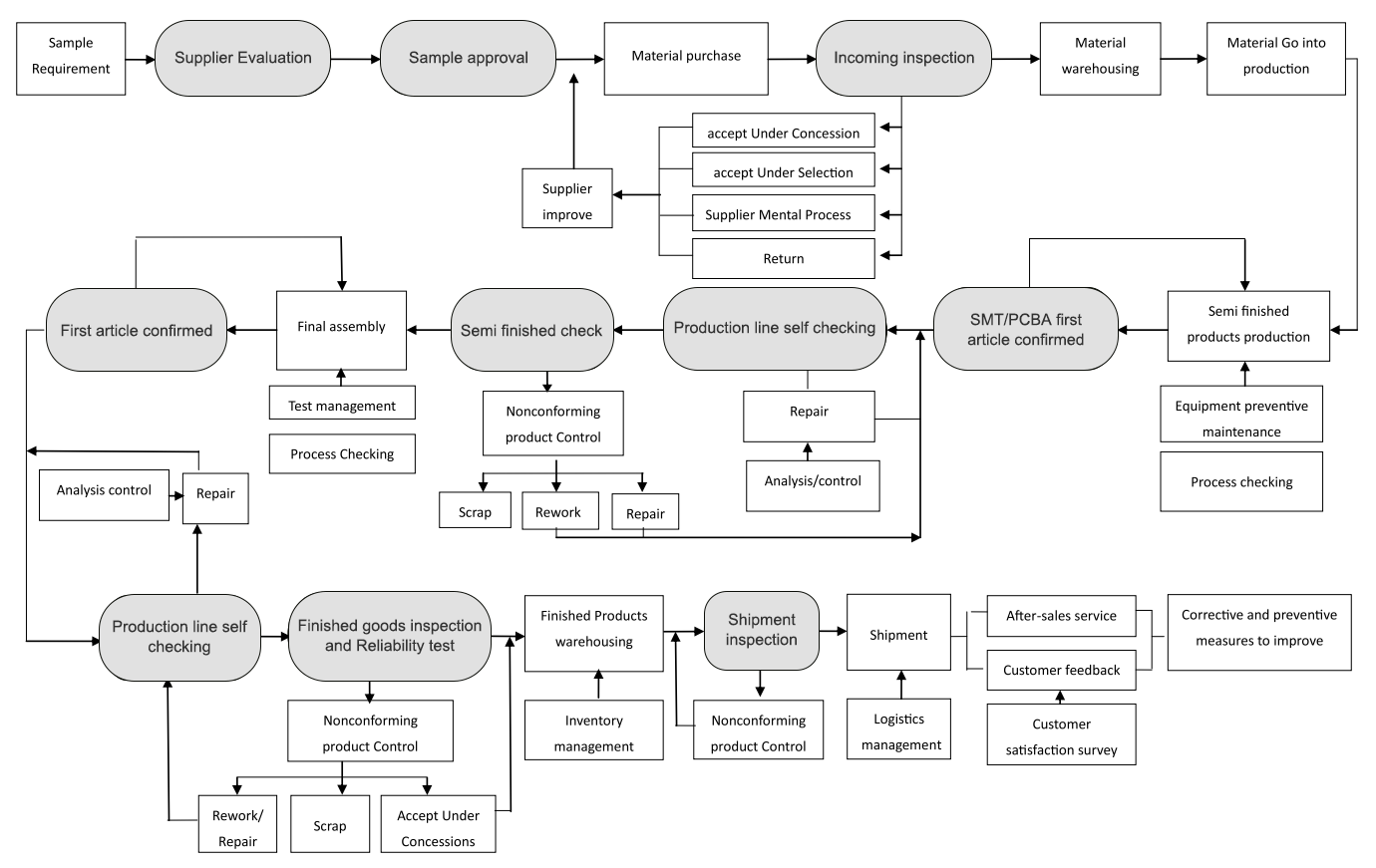

Step 7: Tooling, SMT, and Mass Production Preparation

Once validation and certification are completed, the project enters mass production preparation.

Key Manufacturing Capabilities

● In-house SMT lines for quality and traceability control

● Automated optical inspection (AOI) and X-ray inspection

● End-of-line (EOL) functional testing

● Burn-in and aging tests

A large-scale manufacturing facility enables flexible capacity planning and consistent quality for long-term OEM supply.

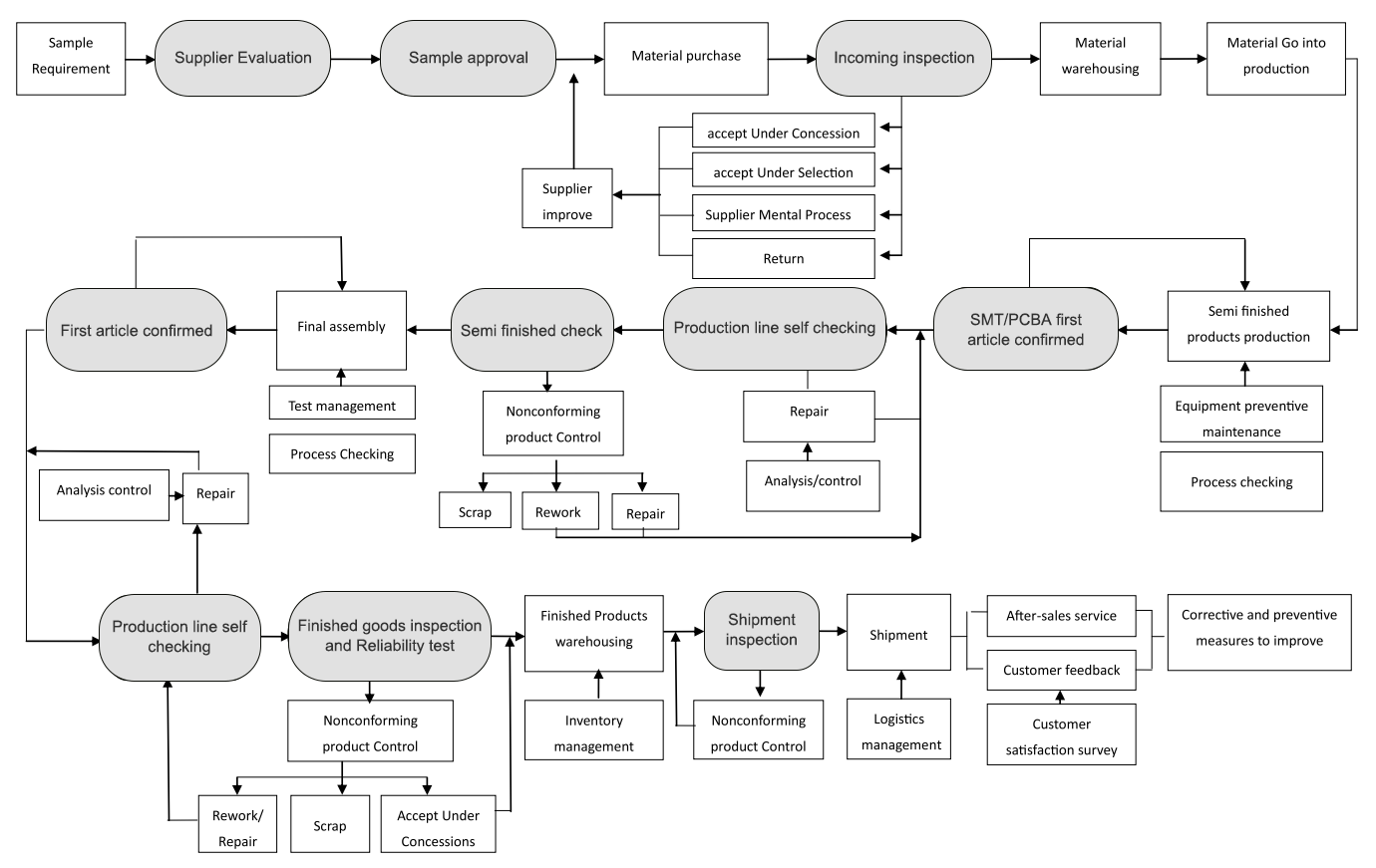

Step 8: SOP, Quality Control, and Lifecycle Support

Successful SOP (Start of Production) is only the beginning.

Ongoing Support

● Quality monitoring and continuous improvement

● Software maintenance and version updates

● Field issue analysis and corrective actions

● Spare parts and service support

OEM car radio development projects typically span several years, making long-term supplier stability a key evaluation factor for automotive manufacturers.

Choosing the Right OEM Car Radio Development Partner

For automotive manufacturers, selecting the right OEM car radio partner is as important as the technical solution itself.

Key Evaluation Criteria

● Proven experience in OEM automotive projects

● Strong hardware and software engineering teams

● In-house SMT and large-scale manufacturing capability

● Experience with wireless CarPlay modules and digital dashboard clusters

● Ability to support global compliance and long-term supply

An experienced OEM car radio manufacturer acts not only as a supplier but as a long-term technology partner.

Conclusion

OEM car radio development projects require systematic planning, technical expertise, and manufacturing excellence. From requirement definition to mass production and lifecycle support, each step plays a critical role in ensuring product stability, compliance, and brand consistency.

For automotive manufacturers seeking reliable OEM car radio solutions, working with an experienced partner that combines engineering capability, in-house manufacturing, and global project experience is the key to long-term success.

By following these key steps, automotive OEMs can reduce project risks, shorten development cycles, and deliver high-quality in-vehicle infotainment systems to the global market.

English

English Russian

Russian